Roland Quality Rock Steaday

RF-650 Central Surface coiling and slitting machine.

This Machine is suitable for the width of the finished products is 5MM-35MM narrow slitting,and the finished reeled with backrest,and the tension of the finished products is stable.

Machine detail feature

Operation principle

Raw materials are rewinding or slitting from the traction main machine to the slitting mechanism.

Main components of the machine

This machine is composed of the rectifying and unwinding

mechanism, slitting mechanism,

winding mechanism, driving mechanism and electrical control.

Characteristic

The machine is composed of computer control, single ultrasonic tracking and deviation correction

system, automatic adjustment of winding tension and linkage motor and mechanical structure.

The unwinding tension is controlled by magnetic powder brake and automatic tension. The

winder adopts the air expanding shaft, which can automatically rise and fall with the help of

automatic air pressure. The frequency converter controls the working speed of the whole

machine and is equipped with an automatic meter counting device. The utility model has the

advantages of smooth incision, neat end face of winding, convenient for subsequent processing,

etc.

Slitting mechanism

The mechanism adopts the high-precision disc disc disc cutter of cemented carbide, with neat cut

and long service life. The upper and lower cutter shafts are cut by adjusting the width, and the

speed of the upper and lower cutter shafts is matched by gears. Rotate the hand wheel to lower

the knife, and rotate the handle to realize automatic knife leaning.

Transmission mechanism

The frequency converter is used to control the operation of the main motor. The speed is

convenient and fast, and the speed adjustment is too soft and stable.

Main electrical appliances

Adopt human-machine interface, PLC centralized control, advanced technology

Human machine interface, display and set the host speed and winding length, set the unwinding

and winding tension and taper

Centralized electric cabinet control, beautiful and easy to operate.

PLC built-in meter counting function, real-time linear speed, meter recording automatic stop

function (with deceleration stop function, meter recording basically has no error)

A:strong expansibility.upgrade system or custom personalize design

B:Modular design: more convenience and powerful

C:machine parts characters :use the high quality raw material ,

Long using lifetime and high stability

D:machine process :according international standard process

Quenching tempering internal /external procession grinding.

CNC ,wine cutting ,milling ,drilling ,ensured each part procession And durable.

Q&A

1.Q: Can you accept OEM or ODM?

A: Yes, you just need to send us your design, we will offer our best quotation within 24 hours.

2.Q: Do you provide samples? Is it for free?

A: Existing Sample for free, can deliver immediately. Customized sample need sample charge, will be completed within 3-7days. Freight cost will be at your side.

3.Q: Can you do the design for us?

A: Yes, We have a professional team having rich experience in designing paper products.

4.Q: What kind of artwork file format I should provide you for printing?

A: PDF,AI,CDR,PSD,Adobe,Core IDraw, etc.

5.Q: How can you ensure the quality inspection?

A: On the order process,we have inspection standard before delivery and will supply you the pictures

6. Lead time

Kn95 mask machine within 4days.

Our service

Sample service:

-We provide free samples for our existing products range.

-Sample and tooling charges need if special design needed, the exact charges depends on your final design and product.

-We will return sample charges to you once place an order, and return the tooling charges once the order quantity reach to certain quantity.

-It will take 2-3days for free samples.

Customized services:

- We provide OEM and ODM process Service, also Provide product sketch.

After-sale services:

- For most of our products, we provide one year warranty.If any items broken for unartificial reason, we can replace the items after having the approve. We guarantee your satisfaction with all our merchandise. The feedbacks will be paid more attentions from customers constant, we will solve the problems timely.

Patent&Honor

RF-650 Central Surface coiling and slitting machine.

This Machine is suitable for the width of the finished products is 5MM-35MM narrow slitting,and the finished reeled with backrest,and the tension of the finished products is stable.

1.Machine Correction using AC ultrasonic system,With ultrasonic detection of material edges and automatic identification of the material.Machine is driven by the AC motor, with sensitive response and accurate tracking.

2.The material receiving and unloading is swing out type, without unloading, which can reduce the labor intensity. All rolls on the glued surface are covered with anti sticking materials.

3.The whole device is user-friendly with the function of 10-inch touch screen man-machine interface, PLC centralized control, the design of switch buttons, adjustment handles, signs, colors, etc.It meets the requirements of ergonomics and national safety and quality inspection standards.And the functions of digital display, variable frequency speed regulation, intelligent fixed length shutdown, emergency shutdown, overload protection are all available.

2.The material receiving and unloading is swing out type, without unloading, which can reduce the labor intensity. All rolls on the glued surface are covered with anti sticking materials.

3.The whole device is user-friendly with the function of 10-inch touch screen man-machine interface, PLC centralized control, the design of switch buttons, adjustment handles, signs, colors, etc.It meets the requirements of ergonomics and national safety and quality inspection standards.And the functions of digital display, variable frequency speed regulation, intelligent fixed length shutdown, emergency shutdown, overload protection are all available.

| Main Technical parameters | ||

| Name | Parameters | |

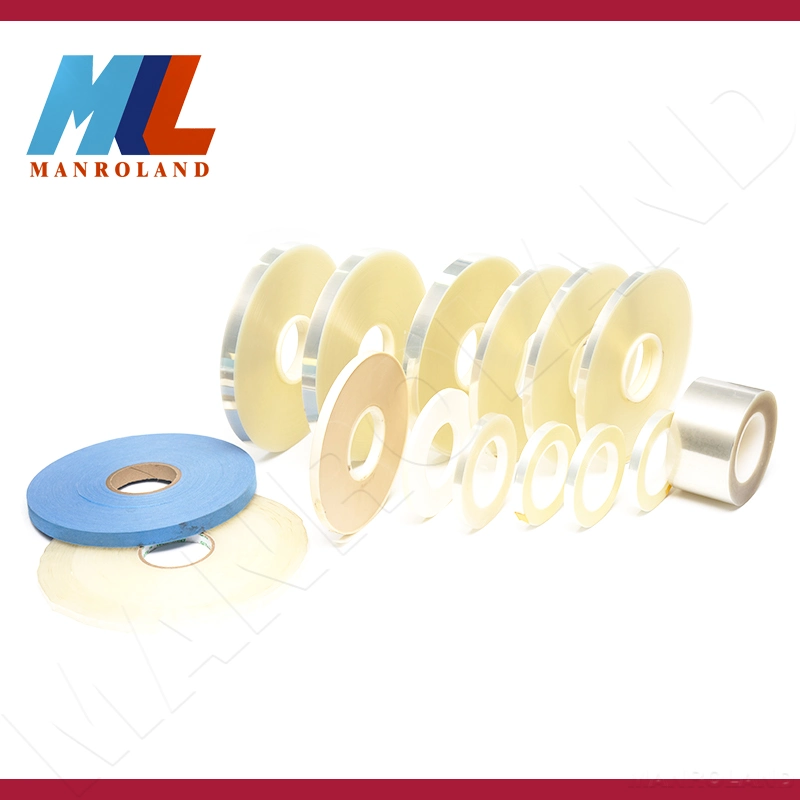

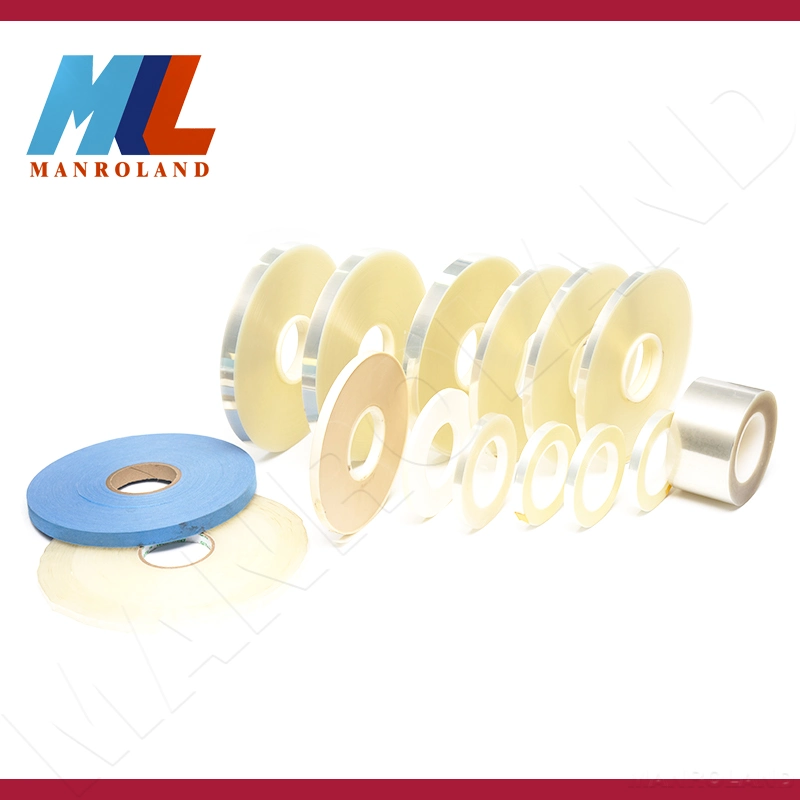

| 1 | Material | Cutting Material:Protective film,PET,OPP,Material with Film,Paper and other coil |

| 2 | Raw material width | 650mm(wheel face width 1700mm) |

| 3 | Maximum unwinding diameter | Φ600 mm (Unwinding effective width 1400mm * paper tube width) |

| 4 | Maximum take-up diameter | Φ550 mm |

| 5 | Minimum slitting width | 5mm - 650mm |

| 6 | Uniformity of cut end face | ±0.1 mm(accuracy of ±0.1 with round knife) |

| 7 | Inside diameter of take-up die | 3"(76.2mm) |

| 8 | Mechanical running speed | 0- 280 M/min(Design speed,due to the material characteristics) |

| 9 | Power Supply | 380V 50HZ 3PHASE |

| 10 | Total machine power | 8 KW |

| 11 | Air pressure source | 5KG (Prepared by customer) |

| 12 | Machine size | Length 2350 mm* width 1850 mm* height 1260 mm |

| 13 | Machine weight | 1500KG (Integrated machine) |

| 14 | Tension control method | Auto-Control |

| 15 | Edge correction System | Ultrasonic AC rectification |

| 16 | Slitting method | Circular knife cutting(razor slitting option) |

| 17 | Aluminum spacer size | (Customized according to cutting width) |

Machine detail feature

Operation principle

Raw materials are rewinding or slitting from the traction main machine to the slitting mechanism.

Main components of the machine

This machine is composed of the rectifying and unwinding

mechanism, slitting mechanism,

winding mechanism, driving mechanism and electrical control.

Characteristic

The machine is composed of computer control, single ultrasonic tracking and deviation correction

system, automatic adjustment of winding tension and linkage motor and mechanical structure.

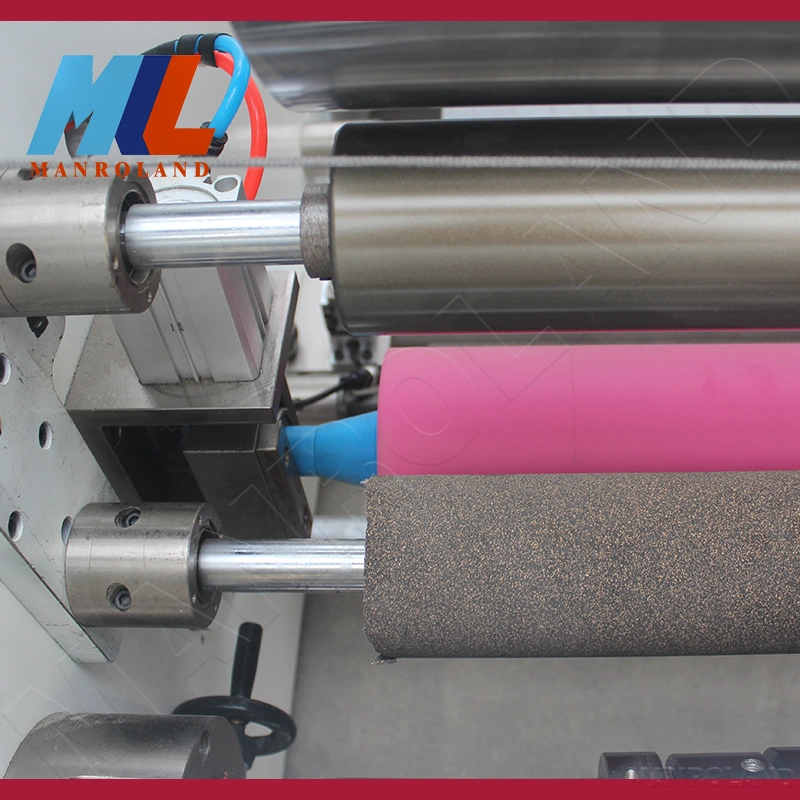

The unwinding tension is controlled by magnetic powder brake and automatic tension. The

winder adopts the air expanding shaft, which can automatically rise and fall with the help of

automatic air pressure. The frequency converter controls the working speed of the whole

machine and is equipped with an automatic meter counting device. The utility model has the

advantages of smooth incision, neat end face of winding, convenient for subsequent processing,

etc.

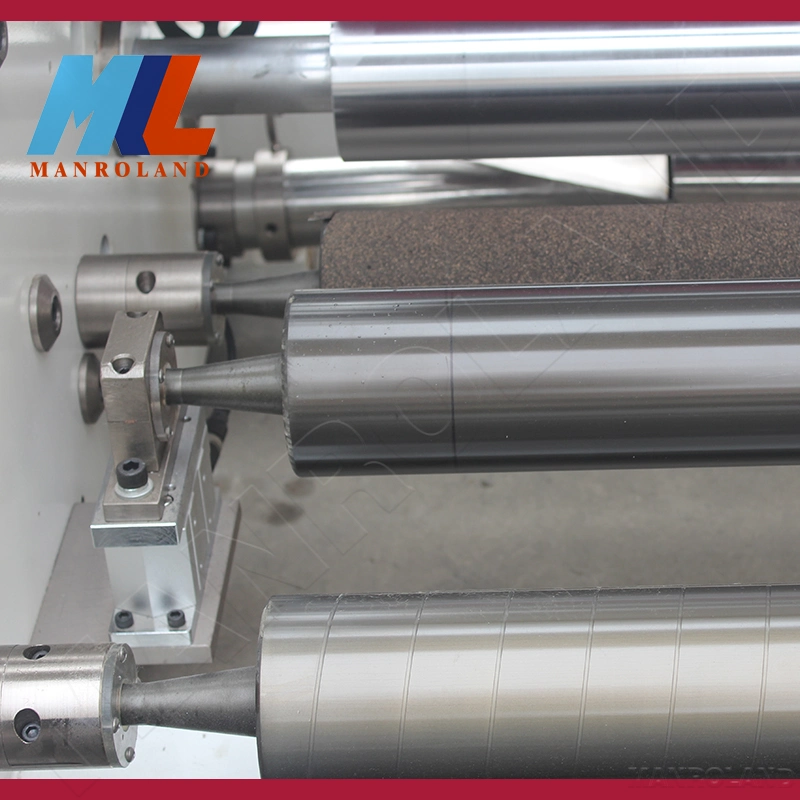

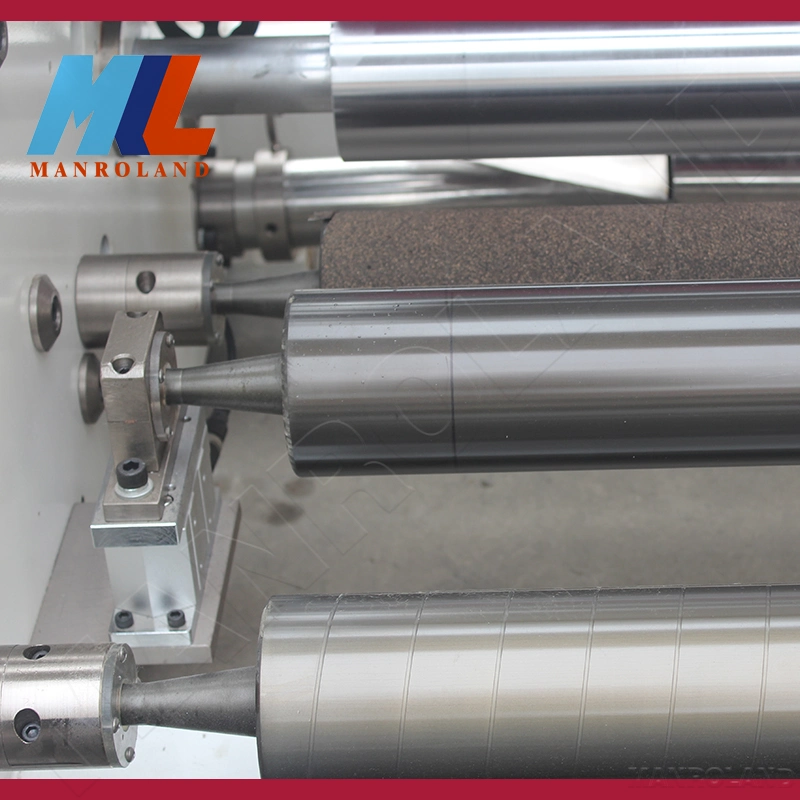

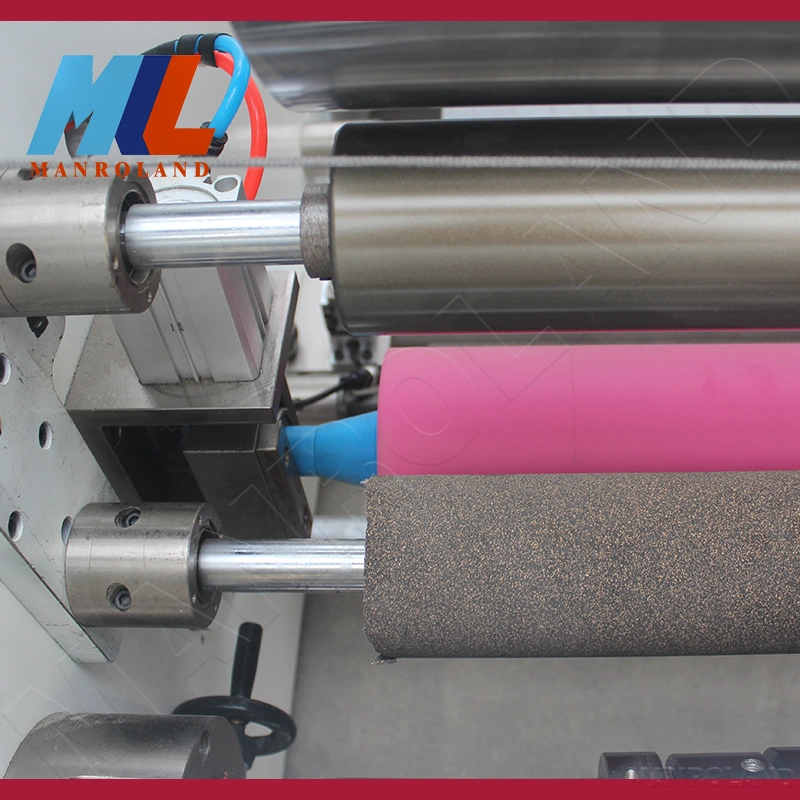

Slitting mechanism

The mechanism adopts the high-precision disc disc disc cutter of cemented carbide, with neat cut

and long service life. The upper and lower cutter shafts are cut by adjusting the width, and the

speed of the upper and lower cutter shafts is matched by gears. Rotate the hand wheel to lower

the knife, and rotate the handle to realize automatic knife leaning.

Transmission mechanism

The frequency converter is used to control the operation of the main motor. The speed is

convenient and fast, and the speed adjustment is too soft and stable.

Main electrical appliances

Adopt human-machine interface, PLC centralized control, advanced technology

Human machine interface, display and set the host speed and winding length, set the unwinding

and winding tension and taper

Centralized electric cabinet control, beautiful and easy to operate.

PLC built-in meter counting function, real-time linear speed, meter recording automatic stop

function (with deceleration stop function, meter recording basically has no error)

About us

DongGuan city ManRoLan procession machinery company Our company integrate produce, sales,R&D as one automatic Industry enterprise. our company have more than 30empoyees Include 5 technicians , 5senior development engineers .our mainly products include: Kn95 mask machine,disposable mask machine high procession slitting machine, full Automatic Cutting machine,laminating machine,...also customize personal customize service. Our products combined with Germany,Sweden,japan etc countr y's high procession technology and quality ,more prizes from our clients our products widely use in electronic . IT, packaging .medicine ,auto ,printing etc industriesOur products have advantages belowA:strong expansibility.upgrade system or custom personalize design

B:Modular design: more convenience and powerful

C:machine parts characters :use the high quality raw material ,

Long using lifetime and high stability

D:machine process :according international standard process

Quenching tempering internal /external procession grinding.

CNC ,wine cutting ,milling ,drilling ,ensured each part procession And durable.

Q&A

1.Q: Can you accept OEM or ODM?

A: Yes, you just need to send us your design, we will offer our best quotation within 24 hours.

2.Q: Do you provide samples? Is it for free?

A: Existing Sample for free, can deliver immediately. Customized sample need sample charge, will be completed within 3-7days. Freight cost will be at your side.

3.Q: Can you do the design for us?

A: Yes, We have a professional team having rich experience in designing paper products.

4.Q: What kind of artwork file format I should provide you for printing?

A: PDF,AI,CDR,PSD,Adobe,Core IDraw, etc.

5.Q: How can you ensure the quality inspection?

A: On the order process,we have inspection standard before delivery and will supply you the pictures

6. Lead time

Kn95 mask machine within 4days.

Our service

Sample service:

-We provide free samples for our existing products range.

-Sample and tooling charges need if special design needed, the exact charges depends on your final design and product.

-We will return sample charges to you once place an order, and return the tooling charges once the order quantity reach to certain quantity.

-It will take 2-3days for free samples.

Customized services:

- We provide OEM and ODM process Service, also Provide product sketch.

After-sale services:

- For most of our products, we provide one year warranty.If any items broken for unartificial reason, we can replace the items after having the approve. We guarantee your satisfaction with all our merchandise. The feedbacks will be paid more attentions from customers constant, we will solve the problems timely.

Patent&Honor